ASTM A269 316 stainless steel exchanger pipe

ASTM A269 316 stainless steel polishing tube:

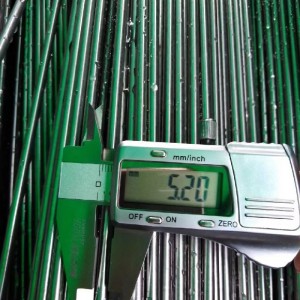

The photo below is 316L stainless steel pipes for heat exchangers intended for our client from Pakistani country

size : OD13.5*0.7 thickness length 6555mm

Product: 316L Stainless Steel Pipes for Heat Exchangers

Material: ASTM A312/A790 316L (Ultra-low carbon, high corrosion

resistance)

Key Features:

- Excellent resistance to pitting/crevice corrosion in chloride environments.

- Ideal for heat exchangers, condensers, and high-temperature applications.

- Smooth surface finish to minimize fouling and enhance thermal efficiency.

- Available in customized sizes, schedules (SCH 10/40/80), and lengths.

Applications: Oil & gas, chemical processing, desalination plants, and power generation.

Compliant with international standards (ASTM, ASME, DIN).

316

Grade 316L (UNS S31603, EN 1.4404) is molybdenum-bearing austenitic stainless steels, which is more resistant to general corrosion and pitting/crevice corrosion than the conventional chromium-nickel austenitic stainless steels such as Grade 304. The low carbon chemistry of 316L combined with an addition of nitrogen enables 316L to meet the mechanical properties of 316.

Grade 316L is often utilized in process streams containing chlorides or halides. The addition of molybdenum improves general corrosion and chloride pitting resistance. It also offers higher creep, stress-to-rupture, and tensile strength at elevated temperatures. In addition to excellent corrosion resistance and strength properties, the Grade 316L Cr-Ni-Mo alloys also provide excellent fabricability and formability which are typical of the austenitic stainless steels.

Stainless Steel coil products:

stainless steel coil tube

stainless steel tube coil

stainless steel coil tubing

stainless steel coil pipe

stainless steel coil tube suppliers

stainless steel coil tube manufacturers

stainless steel pipe coil

PROPERTIES

Grade 316L may be considered for a wide variety of applications where one or more of the following properties are important:

Resists atmospheric corrosion, more resistant than Grade 304

Resists corrosion in polluted marine atmospheres

Heat Resistance

Heat Treatment

Prevention of product contamination

Resistance to oxidation

Easily welded and processed by standard shop fabrication practices.

Excellent formability

Hot and cold working

Beauty of appearance

Ease of cleaning

Good strength and toughness at cryogenic temperatures

Ready availability of a wide range of product forms

CHEMICAL COMPOSITION AND PHYSICAL PROPERTIES FOR 316L

| Item | C% | Si% | Mn% | P% | S% | Ni% | Cr% | Mo% | N% | Others |

| Min | — | — | — | — | 10.00 | 16.00 | 2.00 | — | — | |

| Max | 0.030 | 0.750 | 2.00 | 0.045 | 0.030 | 14.00 | 18.00 | 3.00 | 0.100 | — |

| Item | Tensile Test | Hardness Test | ||||

| 0.2%Y.S. | 1%Y.S. | T.S. | EL (%) | HRB | HV | |

| Min | 170 | — | 485 | 40 | — | — |

| Max | MPa | — | MPa | — | 95 | — |

APPLICATION

The high corrosion resistance of 316L allows for its use in widely range of industries, includes:

Food preparation equipment

Chemical processing for inks, rayons, photographic chemicals….

Laboratory benches and equipment

Rubber, plastics, pulp & paper machinery

Pollution control equipment

Boat fitting, value and pump trim

Heat exchangers

Pharmaceutical industries, surgical and medical implants, including pins, screws and orthopaedic implants

Condensers, evaporators and tanks

Architecture and marine applications

Specification:

Item:stainless steel polishing pipe

Type:welded or seamless

Standard:ASTM A554 JIS ,DIN

Grade:201,202, 304, 304L,316, 316L,409, 430,etc

Size:Round pipe:OD 8-219m

Square Pipe: OD 10x10mm -150x150mm

Rectangle Pipe:10x20mm to 120x180mm

Thickness:0.2-4.0mm

Pipe surface:180G, 320G, 400G, 500G, 600G,Satin, hairline, 2B,BA, mirror,8K

Pipe length:5.8m 6M 11.85M 12m

Application:

1.Decoration usage(road,bridge handrail,railing,bus stop,airport and gym

2.Construction and ornament

3.Industry area(petroleum,food,chemical,paper,fertilizer,fabric,aviation and nuclear.

| Square Steel Tube(mm) | Rectangular Steel Tube (mm) |

Round Steel Tube (mm) |

| 10×10×0.6~3.0 | 10×20×0.6~3.0 | 6×0.6~1.0 |

| 15×15×0.6~3.0 | 20×30×0.6~3.0 | 12×0.6~1.5 |

| 20×20×0.6~3.0 | 20×40×0.6~3.0 | 13×0.6~1.5 |

| 25×25×0.6~3.0 | 25×50×0.6~3.5 | 16×0.6~2.0 |

| 30×30×0.6~3.5 | 30×50×0.6~3.5 | 19×0.6~3.0 |

| 40×40×0.6~3.5 | 40×60×0.6~3.5 | 20×0.6~3.0 |

| 50×50×0.6~3.5 | 40×80×0.6~3.5 | 22×0.6~3.0 |

| 60×60×0.6~3.5 | 60×80×1.0~6.0 | 25×0.6~3.0 |

| 70×70×0.6~3.5 | 50×100×1.0~6.0 | 27×0.6~3.0 |

| 75×75×0.6~3.5 | 60×120×1.0~6.0 | 32×0.6~3.0 |

| 80×80×1.0~6.0 | 80×120×2.0~8.0 | 40×0.6~3.5 |

| 100×100×2.0~8.0 | 80×160×2.0~8.0 | 38×0.6~3.0 |

| 120×120×2.0~8.0 | 100×150×2.0~8.0 | 48×0.6~3.5 |

| 150×150×2.0~8.0 | 100×200×2.0~8.0 | 60×0.6~3.5 |

| 200×200×4.0~16.0 | 150×250×4.0~12.0 | 76×0.6~3.5 |

| 250×250×4.0~16.0 | 200×300×4.0~16.0 | 89×1.0~6.0 |

| 300×300×4.0~16.0 | 300×400×4.0~16.0 | 104×1.0~6.0 |

| 400×400×4.0~16.0 | 300×500×4.0~16.0 | 114×1.0~6.0 |

Quality advantage:

The quality of our products for the control line in oil and gas sector is assured not just during the controlled manufacturing process but also by way of finished product testing. Typical tests include:

1.Non-destructive tests

2. Hydrostatic tests

3.Surface finish controls

4. Dimensional accuracy measurements

5.Flare and coning tests

6. Mechanical and chemical property testing

Application caillary tube

1) Medical device industry

2) temperature-guided industrial temperature control, sensors used pipe, tube thermometer

3) Pens care industry core tube

4) micro-tube antenna, various types of small precision stainless steel antenna

5) With a variety of electronic small-diameter Stainless steel capillary

6) Jewelry needle punch

7) Watches, picture

8) Car antenna tube, bar antennas using tubes, antenna tube

9) Laser engraving equipment to use stainless steel tube

10) Fishing gear, accessories, Yugan out with possession of

11) Diet with stainless steel capillary

12) all types of mobile phone stylus a computer stylus

13) Heating pipe industry, oil industry

14) Printers, silent box needle

15) Pull a double-melt stainless steel tube used in window-coupled

16) A variety of industrial small diameter Precision stainless steel tubes

17) Precision dispensing with stainless steel needles

18) Microphone, headphones and microphone to use stainless steel tube, and so on